Power Station Check Valve

Introduction:

The valve whose opening and closing parts can be opened or closed by the medium flow and force to prevent the medium backflow is called a check valve. The check valve is an automatic valve, which is mainly used on the pipeline with one-way flow of medium. It only allows the medium to flow in one direction to prevent accidents.

Medium backflow: ① the sealing surface is damaged; ② Inclusion of impurities. Repairing the sealing surface and cleaning impurities can prevent backflow.

Purpose of H61Y welding power station check valve:

It is applicable to pipelines under various working conditions such as petroleum, chemical industry and thermal power station with class 1500-2500lb and working temperature of – 29-570 ℃. Applicable media: water, oil, steam, etc.

Feature:

1. The product is designed and manufactured according to ANSI B16.34 and E101 standards, and can be equipped with imported equipment.

2. The pressure self tightening sealing structure is adopted in the middle chamber of the valve. The higher the pressure of the inner chamber, the better the sealing performance. Both ends of the branch pipe are:

3. The two ends of the branch pipe are butt welded to meet different requirements of the connecting pipe.

4. The pressure resistant parts of the valve are made of high-quality heat-resistant alloy steel, with good high temperature performance, high pressure resistance, durability, safety and reliability.

5. The sealing surface of valve disc and valve seat is made of Stellite cobalt based hard alloy, which is wear-resistant, high-temperature resistant, good scratch resistance and long service life.

6. The valve disc rotates around the pin shaft outside the valve seat to reduce violent impact during closing.

7. The built-in pin shaft structure reduces the external leakage point and makes the use more reliable.

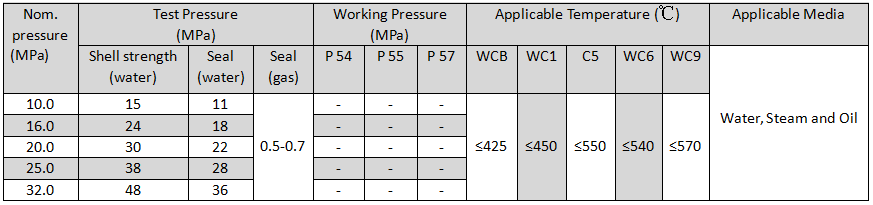

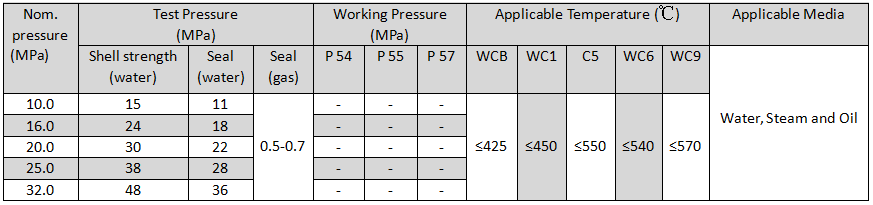

Parameter:

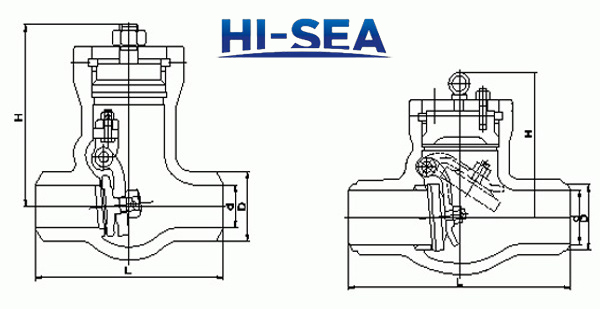

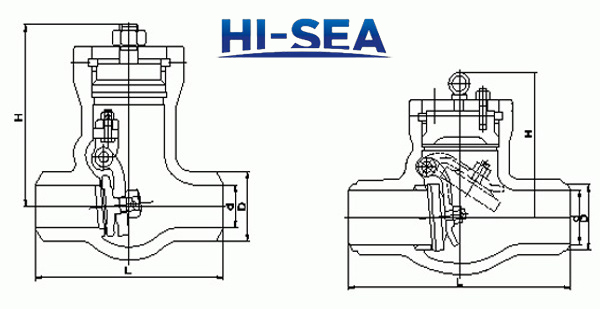

Drawing: