Axial Flow Type Regulating Valve

Introduction:

Axial-flow regulating valve refers to the straight-through streamlined flow channel with straight line symmetry and barrier-free in the valve body cavity. The design of this inner cavity can make the medium pass through very easily, and the fluid is evenly distributed in various positions inside the valve, thereby reducing the local flow of the fluid. High flow rate, turbulent flow, jet flow and other impacts improve the stability of the valve and minimize turbulence and noise.

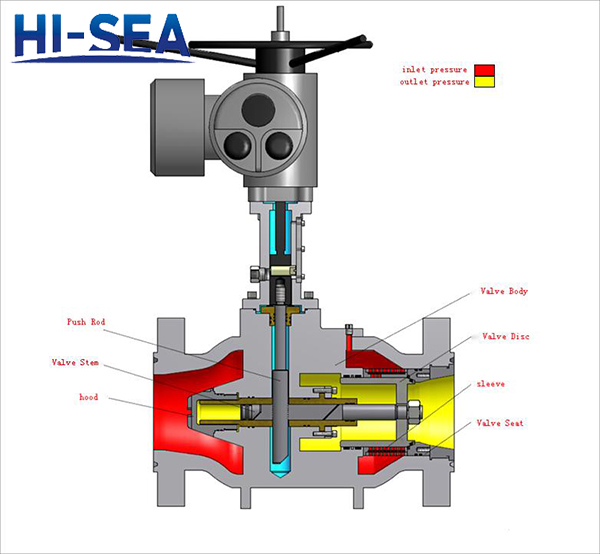

The valve is mainly composed of the valve body, push rod, valve stem and valve core, sleeve, valve seat and other main components. regulation, so as to achieve the purpose of throttling regulation.

Features:

1. The axial flow control valve has an axial flow design with a smooth flow channel, which makes the internal resistance of the valve very small, the flow capacity per unit diameter is very strong, and the noise and vibration are low. The balanced spool design makes the torque required by the valve independent of the differential pressure across the valve. The integral casting of the valve body reduces the leakage point, and the tightness is strong, the rigidity is good, and the weight of the valve is small. According to the user’s process conditions, the design of the sleeve is optimized, so that the control range of the valve is large, the noise is reduced, and the control ability is enhanced. The valve operates reliably and can be maintained for long periods of time.

2. The axial flow control valve is durable, low cost, high performance, and excellent design makes it very high in total efficiency in various applications. Due to the axially symmetric flow channel, indirect flow and unnecessary flow direction changes are completely avoided, therefore, the formation of noise and turbulence is greatly reduced. The axial flow regulator design maximizes flow capacity per unit diameter compared to traditional designs.

3. Small holes are evenly distributed around the sleeve of the axial flow valve. The axial flow valve body of this design ensures even distribution of the fluid. The fluid flowing out through the hole on the sleeve is concentrated in the radial direction of the valve, so that the impact on the axis of the fluid valve cancels each other out. Without contacting the valve body and other parts of the valve, the energy of the fluid itself is dissipated inside the sleeve. Therefore, the decompression is carried out through the sleeve. The design controls flow rate, eliminates wear and vibration, and is suitable for gas and oil control.

Main Parameters:

| Nominal Size |

DN50~800 |

| Nominal Pressure |

Class300~900 |

| Body Material |

A352LCC, Cast Steel A216WCB |

| Linear |

≤±1% |

| Hysteresis |

≤1% |

| Design Temperature |

-46℃~+60℃, -29℃~+60℃, |

| Suitable medium |

Natural Gas, Liquefied Petroleum Gas, Petroleum and lique-filed chemicals |

Product Structure Drawing:

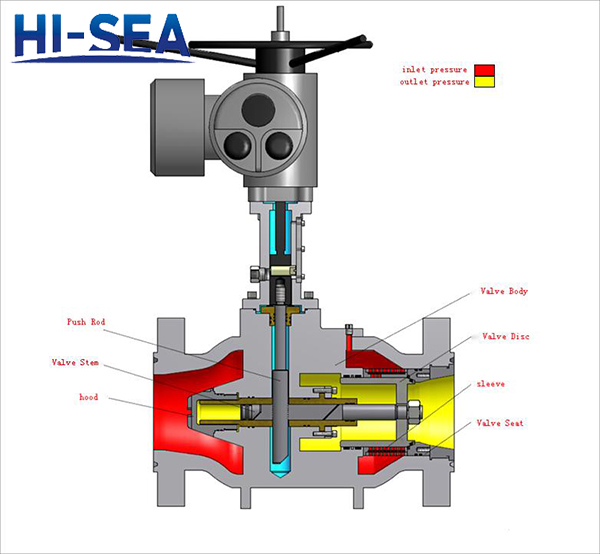

Product Showing: