Bellows Gate Valve

Introduction:

The opening and closing parts of the corrugated pipe gate valve are plug shaped valve clack, the sealing surface is flat or conical, and the valve clack moves in a straight line along the centerline of the fluid. The movement forms of the valve stem include lifting rod type (the valve stem rises and falls, and the hand wheel does not rise and fall) and lifting rotary rod type (the hand wheel and the valve stem rotate together to rise and fall, and the nut is set on the valve body). The corrugated tube globe valve is only applicable to full opening and full closing, and is not allowed to be adjusted or throttled. This type of valve shall be installed horizontally in the pipeline.

Key points of installation:

1. The installation position, height and inlet and outlet directions must meet the design requirements, and the connection should be firm and tight.

2. The handle of all kinds of manual valves installed on the insulation pipeline shall not be downward.

3. Visual inspection must be carried out before the installation of the valve, and the nameplate of the valve shall comply with the provisions of the current national standard General Valve Marking (GB 12220). For valves with working pressure greater than 1.0 MPa and which can cut off the main pipe, strength and tightness tests shall be carried out before installation, and they can only be used after being qualified. During the strength test, the test pressure shall be 1.5 times of the nominal pressure, and the duration shall not be less than 5min. The valve shell and packing shall be qualified if there is no leakage. During the leak test, the test pressure is 1.1 times of the nominal pressure; The test pressure shall meet the requirements of GB 50243 standard for the duration of the test, and it is qualified if there is no leakage on the sealing surface of the valve flap.

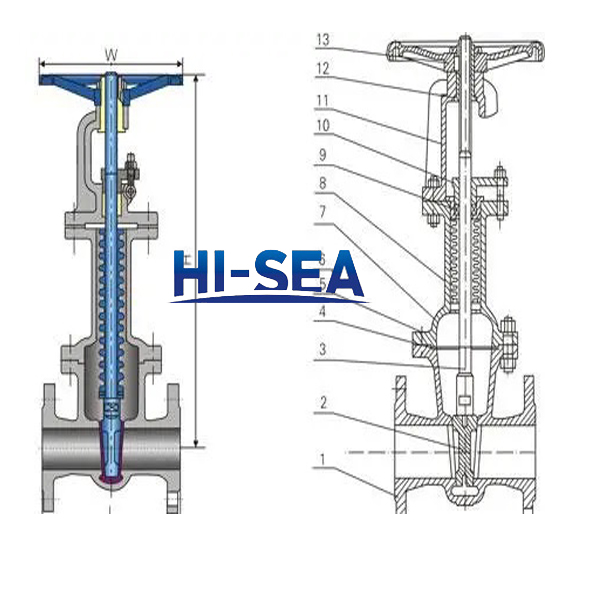

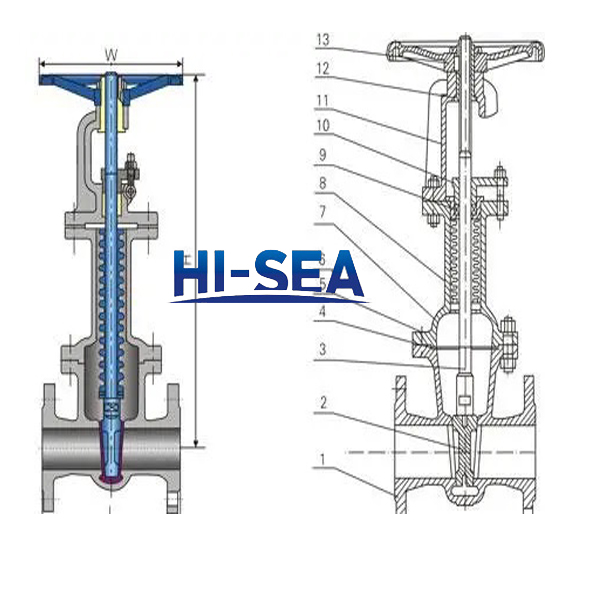

Drawing:

Product Showing: