Female Threaded Diaphragm Valve

Introduction:

Feature thread diaphragm valve is specially used to control non-corrosive or general corrosive media. The surface of the valve body cavity is not lined or covered with various rubbers. It is suitable for different working temperatures and fluid pipelines. The opening and closing of the rubber-lined diaphragm valve is achieved by rotating the handwheel. The upper end of the valve cover is marked with a display color indicating the opening or closing position of the valve to indicate the opening and closing stroke of the valve. When the handwheel is placed clockwise, the handwheel will move down, and the valve flap will drive the diaphragm down to cut off the passage; otherwise, the valve will open.

Features:

1. The opening and closing parts of elastic sealing ensure that there is no internal leakage;

2. The streamlined flow channel makes the pressure loss small;

3. There is no stuffing box, so there is no leakage;

4. The valve body and the cover are separated by the intermediate diaphragm, so that the valve cover, valve stem and other parts above the diaphragm are not eroded by the medium;

5. The diaphragm can be replaced, and the maintenance cost is low;

6. The variety of lining materials can be applied to various media, and has the characteristics of high strength and good corrosion resistance.

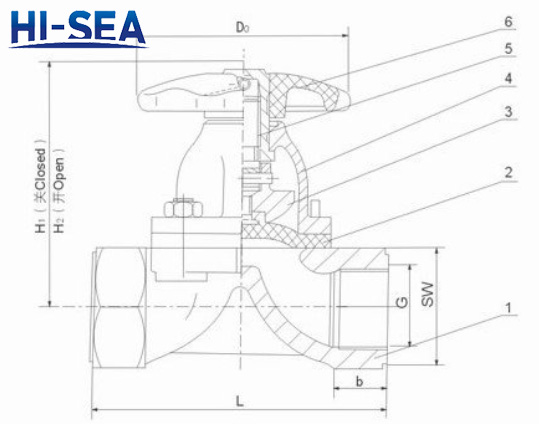

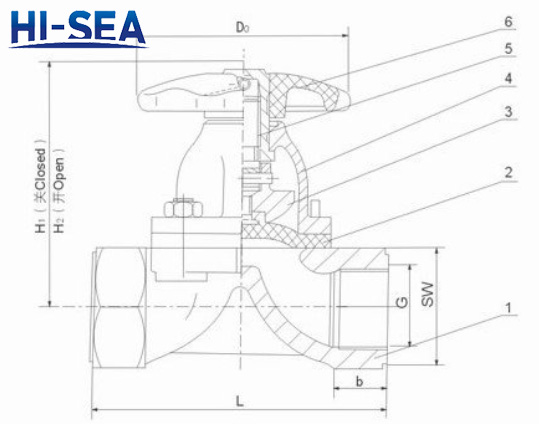

Outline Drawing:

Main Parameters:

| Nominal Size |

Working Pressure |

L(mm) |

SW(mm) |

b(mm) |

H1(mm) |

H2(mm) |

D0(mm) |

Quality(Kg/kilos) |

| DN |

G |

| 8 |

1/4 |

1.6 |

50 |

20 |

– |

60 |

66 |

45 |

0.6 |

| 10 |

3/8 |

50 |

24 |

– |

– |

– |

45 |

0.7 |

| 15 |

1/2 |

65 |

38 |

8 |

84 |

92 |

50 |

0.8 |

| 20 |

3/4 |

85 |

40 |

12 |

93 |

103 |

50 |

1.1 |

| 25 |

1 |

110 |

48 |

18 |

106 |

120 |

66 |

1.9 |

| 32 |

1 1/4 |

120 |

58 |

18 |

137 |

156 |

96 |

3.3 |

| 40 |

1 1/2 |

140 |

69 |

18 |

142 |

163 |

96 |

4.2 |

| 50 |

2 |

165 |

85 |

20 |

167 |

192 |

96 |

5.8 |

| 65 |

2 1/2 |

1.0 |

203 |

60 |

20 |

190 |

225 |

165 |

9.5 |

| 80 |

3 |

254 |

105 |

32 |

206 |

246 |

230 |

16.2 |

Product Showing: