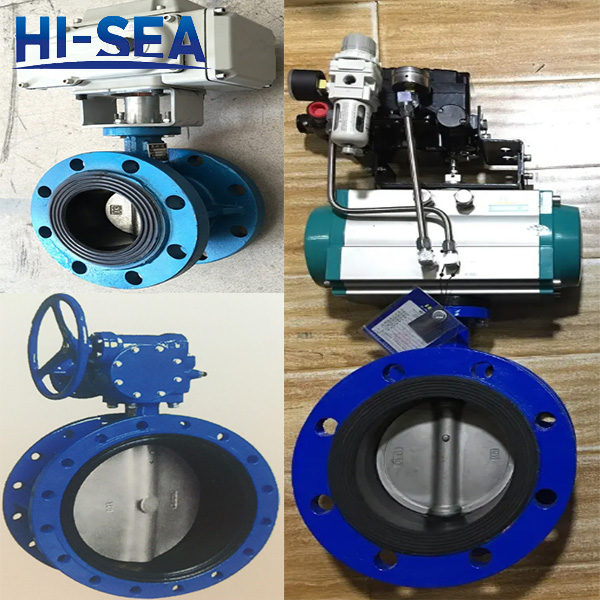

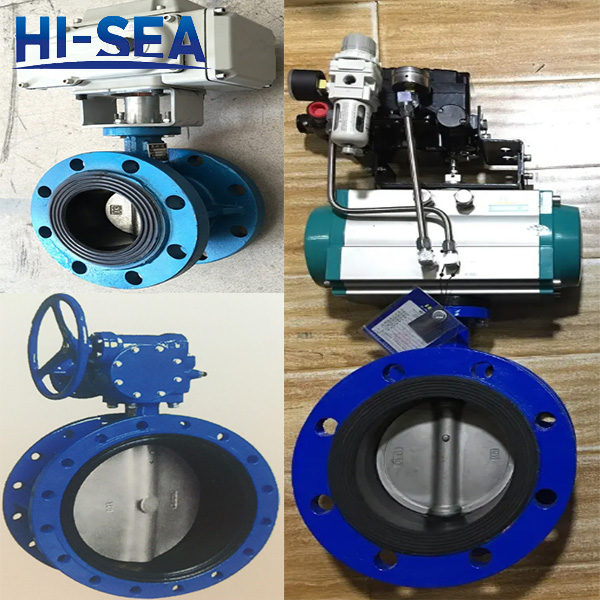

Flange Butterfly Valve

Introduction:

In terms of structure, the flange butterfly valve has a novel design. Because of the particularity of use, the overall size of the flange butterfly valve is small and light in weight; the flange butterfly valve adopts double eccentricity, so it opens and closes quickly, and the operation is light and labor-saving; another important point is that There is no sliding friction between the flange butterfly valve and the sealing ring, which makes the sealing surface wear-resistant.

Flange butterfly valve has long service life, reliable sealing and easy adjustment. The metal-sealed valve of the flange butterfly valve utilizes the inherent cam effect, and the design adopts the principle of triple eccentric structure. The design of its rubber soft sealing butterfly valve adopts a single eccentric structure. The application of these principles leads to the rapid separation between the flange butterfly valve seat and the sealing ring, thereby reducing friction.

Classification:

Soft sealing flange butterfly valve, small overall size, light weight, novel design and structure. The double eccentricity is adopted, so the opening and closing is quick, the operation is light and labor-saving, and there is no sliding friction between the butterfly plate and the sealing ring, which makes the sealing surface wear-resistant, long service life, reliable sealing and easy to adjust.

The hard-sealed flange butterfly valve adopts a three-dimensional eccentric structure, the valve seat and the butterfly plate have almost no friction, and the sealing function is tighter and tighter. Because of the particularity of use, its overall size is small and its weight is light. There is also the use of surfacing stainless steel and cobalt-based cemented carbide to make the sealing surface of the valve body wear-resistant and have a long service life.

Product Showing: