Flange Pneumatic Ball Valve

Introduction:

The pneumatic flange ball valve is composed of high-precision pneumatic actuator and precision cast ball valve. It is mainly divided into two categories: pneumatic flange soft seal ball valve (≤ 180 °) and pneumatic flange hard seal ball valve (≤ 550 °). The pneumatic flanged ball valve has the advantages of compact structure, small volume, reliable operation, low flow resistance coefficient, good sealing, easy maintenance, convenient installation and strong adaptability. The pneumatic flanged ball valve can be equipped with a travel limit switch, a solenoid valve, a pressure reducing valve. The pneumatic flanged ball valve is especially suitable for the occasion where the medium is viscous, containing particles and fibers. This valve are widely used in automatic control systems of petroleum, chemical industry, teaching equipment, light industry, high pressure equipment, pharmacy, paper making and other industries for remote centralized control or local control.

Product features:

(1) The fluid resistance is small, and the ball valve has the smallest fluid resistance among all valves. Even the reduced diameter ball valve has relatively small fluid resistance.

(2) The thrust bearing reduces the friction torque of the valve stem and makes the valve stem operate flexibly for a long time.

(3) The valve seat has good sealing performance. The sealing ring made of PTFE and other materials is easy to seal, and the valve sealing capacity of the ball valve increases with the increase of medium pressure.

(4) The valve stem seal is reliable. Because the valve stem only rotates without lifting, the packing seal of the valve stem is not easy to be damaged, and the sealing capacity increases with the increase of the medium pressure.

(5) Due to the good self-lubricating property of PTFE and other materials, the friction loss with the ball is small, and the service life of the ball valve is long.

(6) The lower mounted valve stem and the convex step of the valve stem head prevent the valve stem from ejecting. If the valve stem seal is damaged due to fire, metal contact can also be formed between the convex step and the valve body to ensure the valve stem seal.

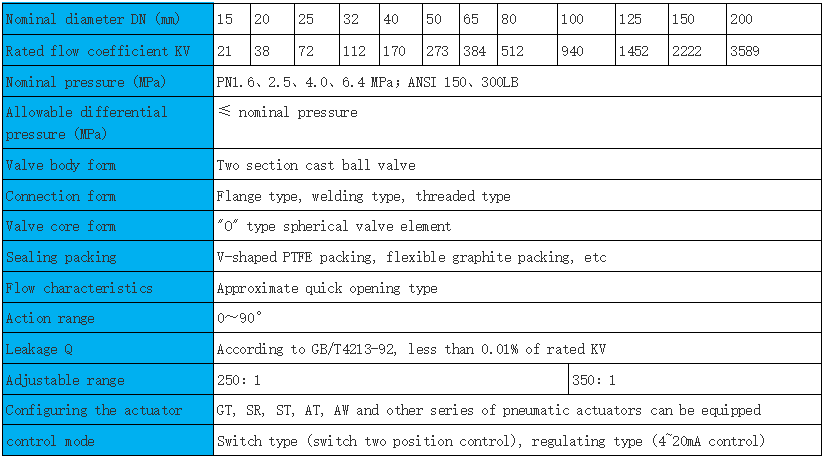

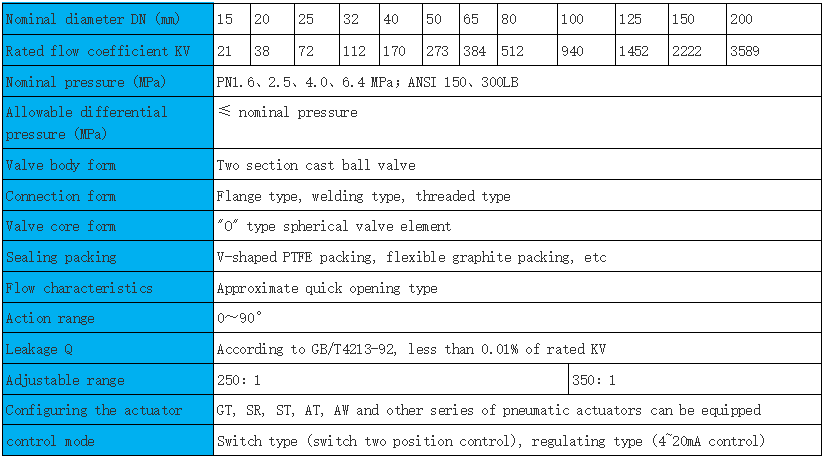

Technical parameter:

Product Showing: