Introduce

Flue Gas Desulfurization Valve is the core control equipment of flue gas desulphurisation (FGD) system in coal-fired power plants, iron and steel metallurgy, chemical industry and other industrial fields, which is specially designed for highly corrosive, dusty, warm and wet flue gas media. It is responsible for accurately controlling the flow of sulphur-containing flue gas, regulating the media flow and resisting the risk of high corrosion, abrasion and scaling of the desulphurisation slurry in wet desulphurisation, semi-dry processes.

Features

Strong corrosion resistance: Duplex stainless steel or nickel-based alloy body or fluorine lining design, resistance to Cl-, SO₃ and other acidic media corrosion.

High temperature resistance: the applicable medium temperature range -40 ℃ to +180 ℃ (special design up to 230 ℃).

Anti-scouring structure: the valve seat and valve plate are strengthened to resist the impact of flue gas dust particles.

Zero leakage sealing technology: multi-level metal hard seal or elastic soft seal combination design.

Bidirectional pressure-bearing capacity: to meet the needs of the system positive and negative pressure switching.

Clamped valve: sealing components can be replaced without dismantling the pipeline.

Flange type valve: online grease injection port design, prolonging the service life of seals.

Application Fields

Power industry: inlet or bypass flue of desulphurisation tower of coal-fired power plant.

Metallurgical industry: used in sintering machine flue gas circulation system and blast furnace gas purification system.

Chemical industry: Sulphuric acid plant tail gas treatment system and wet desulphurisation absorption tower.

Waste incineration: flue gas purification SCR/SNCR system and semi-dry deacidification tower.

Marine Engineering: Exhaust Gas Scrubbing (EGCS) plant for ships and desulphurisation plant for LNG-powered ships.

Application system

| System type |

Valve Type |

Core requirements |

| wet desulphurisation |

Absorption tower inlet valve |

Resistant to Cl⁻ corrosion + anti-gypsum scaling |

| (limestone-gypsum method) |

Circulation pump outlet valve |

Resistant to slurry washout |

| dry desulphurisation |

Reactor regulating valves |

SO₂ high temperature corrosion resistance |

| (SDA semi-dry) |

Dust collector bypass valve |

Quick cut |

Why choose professional desulphurisation flue gas valve?

Industrial flue gas desulphurisation (FGD) is a core part of environmental protection treatment, and valve failure such as corrosion perforation, jamming, etc., will directly lead to system downtime and emission exceedance. Professional desulphurisation flue gas valve through the material science, fluid mechanics and sealing technology of the depth of the integration, in the life cycle to ensure efficient and continuous operation of the system, reduce the comprehensive maintenance costs.

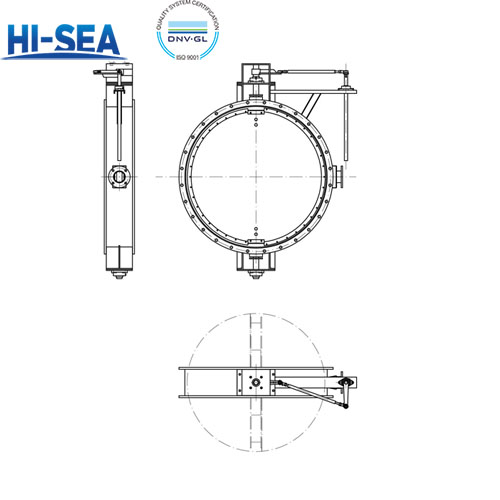

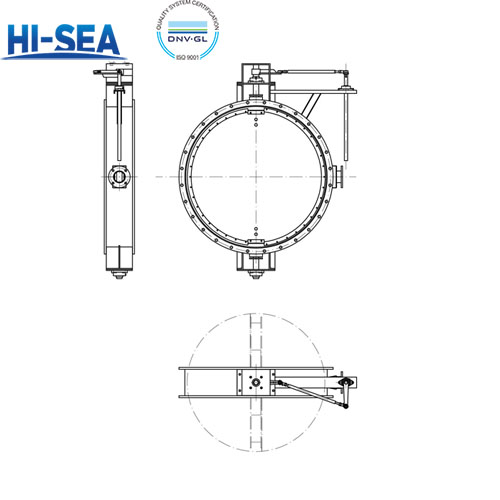

Structure picture