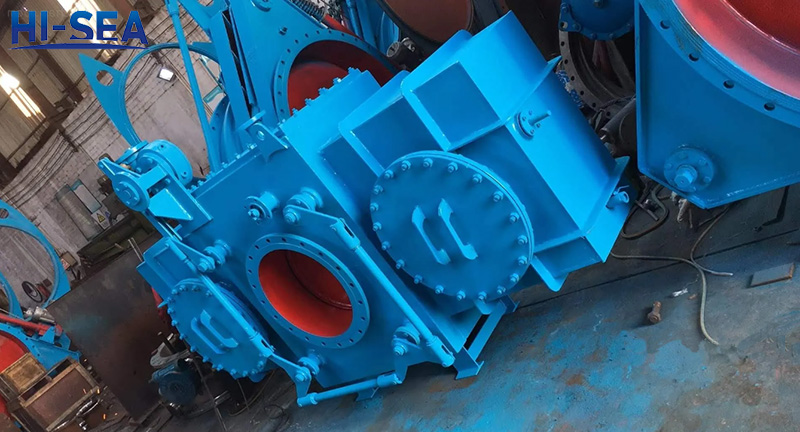

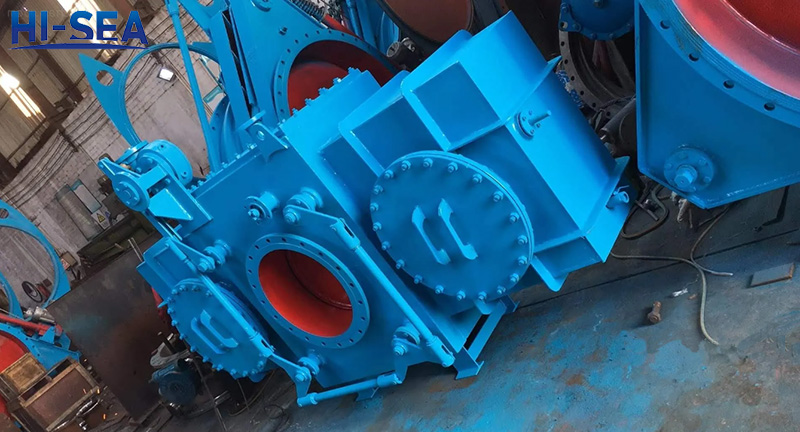

Fully Enclosed Electric Plug-in Valve

Introduction:

The enclosed electric plug-in valve is a closed-type plug-in valve for large-diameter pipeline transportation of gas, especially for the transportation of combustible gas.

The valve box and valve plate composed of the main valve box and the auxiliary valve box have synchronous The transmission mechanism is composed of a top-opening device with an idle stroke, a traversing device that uses the clutch to connect/disconnect the traverse drive device and the traverse mechanism. The traverse mechanism is installed in the main valve box and in the center of the upper part of the valve plate. The compensator is uniformly stressed during the working process, has a low failure rate, and has a long service life. The valve plate travels smoothly and requires little driving power, and the reliability of the valve can be checked without affecting the normal on-off of the pipeline.

Main Structure:

1. Main structural form: closed plug-in valve. The lateral movement of the valve plate and the release and clamping of the valve sealing pair are driven by explosion-proof electric devices. The top opening and pressing adopts an electric screw synchronization mechanism, and the rigid shaft connection is used to ensure reliable synchronization. The valve plate sealing ring adopts special silicone rubber sealing ring, and the sealing pair is special silicone rubber/stainless steel. The movement of the valve plate adopts a two-way rolling structure.

2. In case of power failure or failure, the valve can be opened and closed manually on site.

3. The air-facing side of the guide tube is welded to death, the other end is processed with a stuffing box and filled with packing, and the outer port is sealed with a metal ring and welded firmly. The bellows guide tube is made of thickened 16Mn steel plate with good wear resistance.

4. The traverse mechanism is set above the valve and is driven by stainless steel gear pins, which is wear-resistant, corrosion-resistant and has a long service life.

5. The shaft head seal of the drive shaft of the traverse mechanism adopts the form of packing gland to seal reliably and facilitate maintenance.

6. The valve plate and guide rail can roll in both directions, and the lateral movement and longitudinal movement of the valve plate are rolling friction, which effectively saves power, reduces friction, and prolongs service life. The roller bearings are made of high-temperature self-lubricating powder metallurgy materials, and dust-proof measures are taken to ensure the service life in harsh environments with high temperature and dust, and do not require regular oil injection and lubrication.

7. The valve is equipped with an explosion-proof electric control box, which can realize the side operation and remote control operation.

Product Showing: