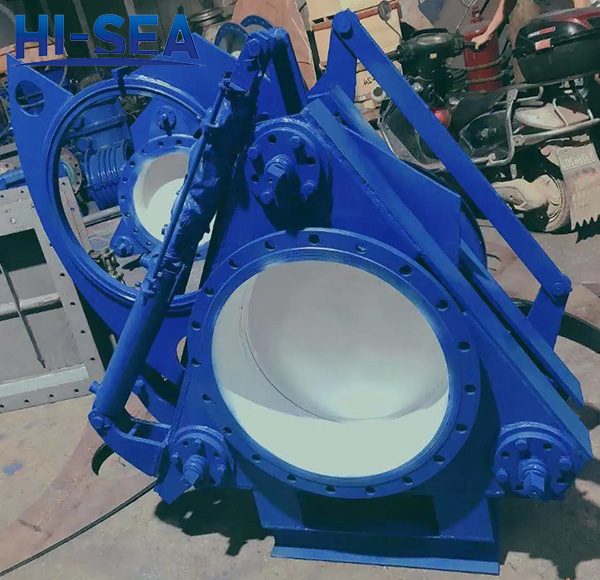

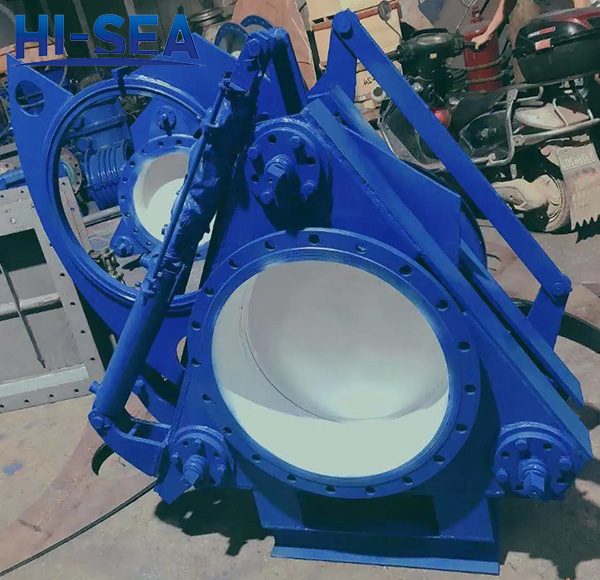

Hydraulic Blind Valve

Introduction:

The hydraulic fan-shaped blind valve is mainly composed of valve body, fan-shaped valve plate (including bellows and electric chain sealing mechanism), flap drive mechanism (including device and reducer) and electronic control system.

The valve body adopts a three-piece square tube frame structure, which has high strength and good rigidity. Under the condition of bearing large external force of the pipeline, it will not cause deformation that affects the normal operation of the valve.

The valve plate has transmission teeth and adopts gear transmission flap, which has stable operation and long service life. The sealing rubber ring is on the valve plate for easy replacement. Equipped with a protective cover, which can effectively protect the internal transmission mechanism. The protective cover is removable for easy maintenance.

When the valve is sealed, the cylinder drives the connecting rod synchronous mechanism to drive the screw mechanism of each pressing point to push the movable valve seat to press the sealing rubber ring, so that the valve plate sealing rubber ring presses the sealing surface of the valve body to achieve sealing. When the valve plate is switched, the electric chain synchronization mechanism drives each point screw mechanism to pull the movable valve seat away from the sealing rubber ring, and drives the valve plate to create a certain gap between it and the sealing surface. Then the electric device and the reducer drive the flap drive mechanism to work, and the gear pushes the valve plate to rotate around the upper central axis to complete the switch from through hole to blind hole (or from blind hole to through hole). Then, press again to seal.

Materials of Main Parts:

Valve body and valve plate: Q235-B

Ripple compensator: 316L, 800, 825, 254SMo according to user requirements

Sealing ring: high temperature resistant special silicone rubber

Product Showing: