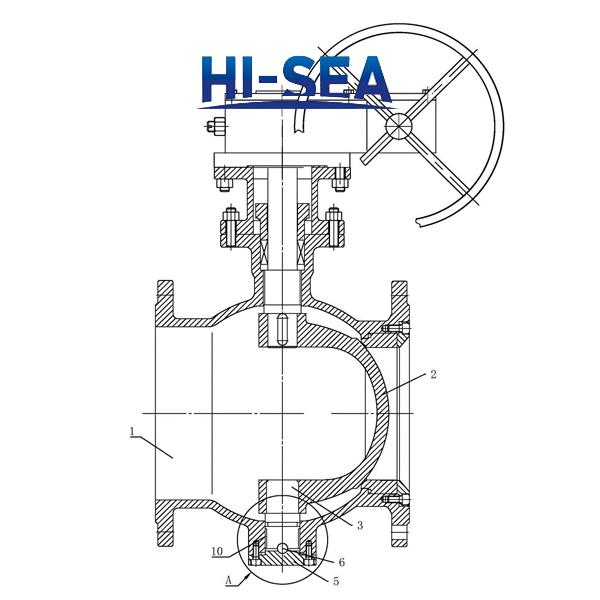

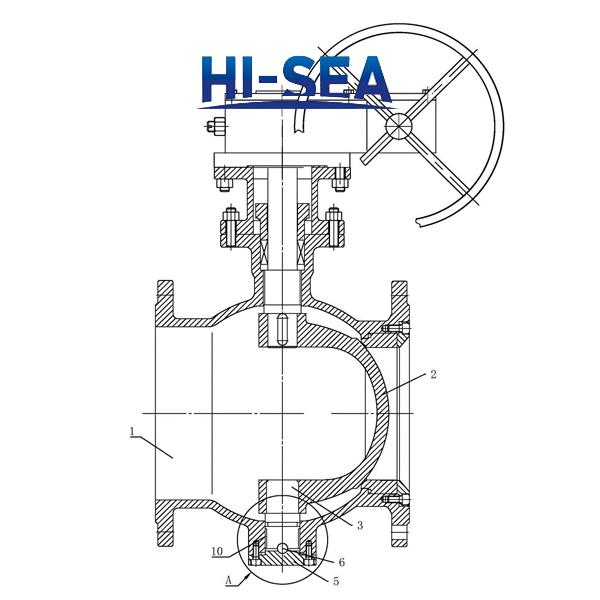

Hydraulically Controlled Eccentric Half Ball Valve

Introduction:

Hydraulically controlled eccentric half ball valve uses eccentric valve body, eccentric ball and valve seat. When the valve rod rotates, it is automatically centered in the common path. The valve rod is closed more tightly during the closing process to achieve good sealing. The ball of the valve is completely separated from the valve seat, which eliminates the wear of the sealing ring and overcomes the problem that the traditional ball valve seat and the ball sealing surface are always worn. The non-metallic elastic materials are embedded in the metal seat, and the metal surface of the valve seat is well protected. This product is especially suitable for steel industry, aluminum industry, fiber, small solid particles, pulp, coal ash, petroleum gas and other media.

Structural characteristics:

1. The valve seat is equipped with a structure where the outer step matches the inner step of the valve body to prevent the ball from jamming or separating from the valve seat.

2. When the eccentric valve body, eccentric ball, valve seat and valve stem are used for rotation, they will be automatically centered in the common path. The valve will be closed more tightly during the closing process to achieve the goal of good sealing, so the eccentric hemisphere valve sealing performance is safe and reliable; When the valve is opened and closed, the ball and the valve seat are completely separated, which eliminates the wear of the sealing pair and overcomes the problem that the traditional valve seat and the ball sealing surface are always worn.

3. The non-metallic elastic material is placed in the metal seat, and the metal sealing surface of the valve seat is well protected.

4. There is a shearing effect between the sphere with hemispherical notch and the valve seat, which is especially suitable for media containing dimension, small solid particles, slurry, etc.

5. When fully opened, the flow capacity is large, the pressure loss is small, and the medium will not be deposited in the cavity of the valve body.

Executive standards:

Design and manufacture: GB12237 - 89

Flange connection: GB/T17241.6998, GB/T9115 (steel)

Structure length: GB12221 - 89

Pressure test: GB/T13927

Drawing:

Product Showing: