Hydrogenation Lift Check Valve

Introduction:

The hydrogenation valves used in the petroleum refining and chemical industry are facing extremely severe working conditions: high temperature, high pressure, hydrogen and hydrogen sulfide. In order to meet the special requirements of the petroleum refining and petrochemical industry for the performance of hydrogenation valves.

Structural features:

1. The product has reasonable structure, reliable sealing, excellent performance and beautiful shape.

2. The sealing surfaces of the valve disc and valve seat are made of cobalt based hard alloy, which is wear-resistant.

3. The valve stem has good corrosion resistance and scratch resistance after tempering and surface nitriding treatment.

Product use:

The hydrogenation lift check valve is suitable for cutting off or connecting the medium on the pipes of petroleum, chemical, pharmaceutical, chemical fertilizer, power industry and other working conditions with the working temperature of – 29 ~ 550 ℃. Applicable medium: water, oil, steam, acid medium, etc. Operation modes include: manual, gear drive, electric, pneumatic, etc.

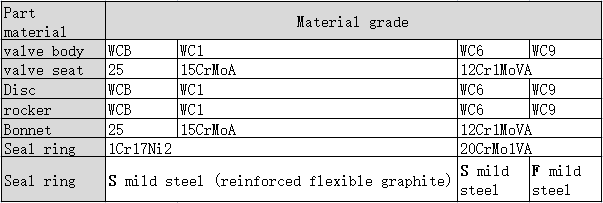

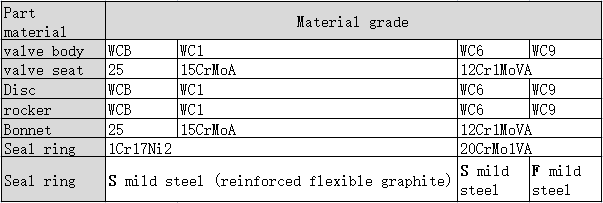

Material of main parts:

Product Showing: