Low Temperature Ball Valve

Introduction:

Thelow temperature ball valve is applicable to the management system of cryogenic liquid storage and transportation equipment. It has the characteristics of flexible switch and reliable sealing, and can also be used for the management system of other cryogenic and cryogenic media.

Features of structural design and processing and manufacturing:

Low temperature ball valves are divided into low temperature floating ball valves and low temperature fixed ball valves. For the temperature above – 50 ℃, the long neck structure is generally not used. For the temperature below – 50 ℃, the neck length T is generally 250mm, or it is determined according to our design and calculation The cryogenic ball valve is mainly used to output liquid cryogenic media such as ethylene, liquid oxygen, liquid hydrogen, liquid nitrogen, liquid ammonia, liquid propane, liquefied natural gas, liquefied petroleum products, etc. It is not only flammable and explosive, but also needs to be gasified when heating up, and its volume expands hundreds of times when gasifying.

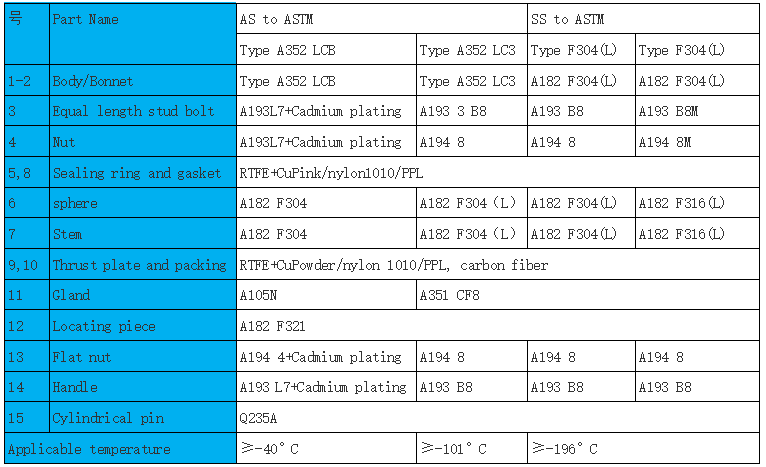

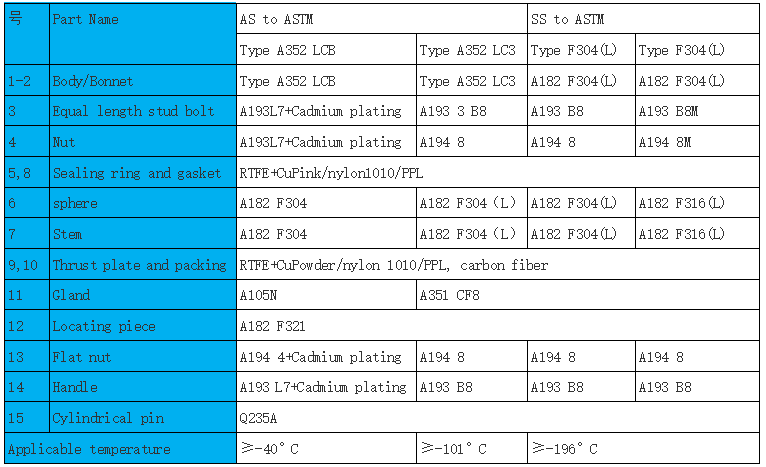

Material selection:

The material of LNG valve is very important. If the material is not qualified, it will cause external or internal leakage of the shell and sealing surface; The comprehensive mechanical properties, strength and rigidity of the parts can not meet the use requirements or even break. Causing LNG medium leakage and explosion. Therefore, in the process of developing, designing and developing LNG valves, the material quality is the primary key issue. The valve body and bonnet are LCB (- 46 ℃), LC3 (- 101 ℃) and CF8 (304) (- 196 ℃)

Materials and main parameters:

Product Showing: