Stainless Steel Knife Gate Valve

Introduction:

Manual stainless steel knife gate valve PZ73W-10P stainless steel gate valve/stainless steel knife gate valve/stainless steel knife gate valve PZ73F/X/Y manual knife gate valve/stainless steel gate valve/stainless steel knife gate valve/stainless steel knife gate valve, It can work normally under working pressure of 0.6MPa~1.6MPa and operating temperature of – 29 ℃~425 ℃. The gate plate of the knife gate valve has the shearing function, which can scrape the adhesive on the sealing surface and automatically remove the debris. The stainless steel gate plate can prevent the seal leakage caused by corrosion. It is suitable for sewage, coal slurry, syrup, slurry, air, slag water mixture, water supply, paper making, mining and other industries.

Structural features:

The opening and closing parts of knife gate valve are gate plates. The movement direction of the gate plate is perpendicular to the direction of the fluid. It can only be fully opened and closed, and cannot be adjusted or throttled. When the knife gate valve is closed, the sealing surface can be sealed only by the medium pressure, that is, the sealing surface of the gate plate is pressed to the valve seat on the other side by the medium pressure to ensure the sealing of the sealing surface, which is called self sealing. Most knife gate valves adopt forced sealing, that is, when the valve is closed, the gate plate shall be forced to the valve seat by external force to ensure the sealing of the sealing surface.

Product features:

1. Ultra short structure length, material saving, can greatly reduce the overall weight of the pipeline system

2. It occupies less effective space, can effectively support the strength of the pipeline, and can reduce the possibility of pipeline vibration

3. The ram is made of austenitic stainless steel, with greatly improved corrosion resistance, which can effectively prevent sealing leakage caused by ram corrosion

4. The upper sealing filler adopts flexible PTFE, which is reliable in sealing and easy to operate

5. The ram has the function of knife switch, which can effectively cut off all kinds of sundries in the circulating medium.

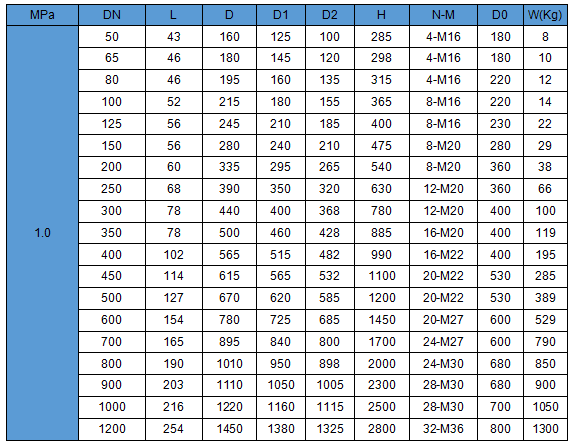

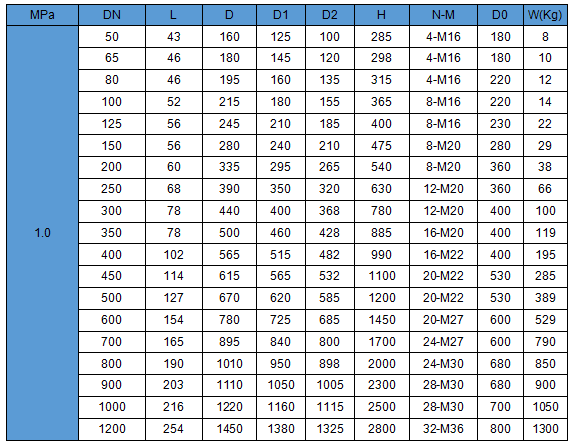

Main outline and connection dimensions (mm):

Product Showing: